After other ground penetrating radar providers failed, US Steel called in the experts. GPR Data LLC responded immediately to Indiana, to resolve a series of concerns in the concrete slab floor of the electrical room in a factory building, and perform deep concrete scanning.

Objective:

Evaluate thickness of concrete slab and locate safe coring positions to add drainage for intruding ground water. Provide a safe drilling plan with locations for pressure grouting and waterproofing the underside of slab.

Evaluate thickness of concrete slab and locate safe coring positions to add drainage for intruding ground water. Provide a safe drilling plan with locations for pressure grouting and waterproofing the underside of slab.

Challenge:

Most importantly, this slab is laced with extremely high voltage electrical conduits. Failure is potentially catastrophic. The floor slab in these areas averages seven feet thick but varies by up to a foot. Concrete mix was high in sulfer, which attenuates the radar signal. Visibility is impeded by a great deal of near-surface rebar, and compounded by slag used as random filler during the original pour.

Results:

The majority of the substation floor was mapped with high precision and accuracy. Evaluating slab thickness and conduit density in various areas, drainage core locations were selected and drilled. The bottom of slab was hit within one inch of projection with zero conflict. GPR Data provided on-site assistance throughout the drilling and grouting process, and have subsequently completed a second substation remediation project as well.

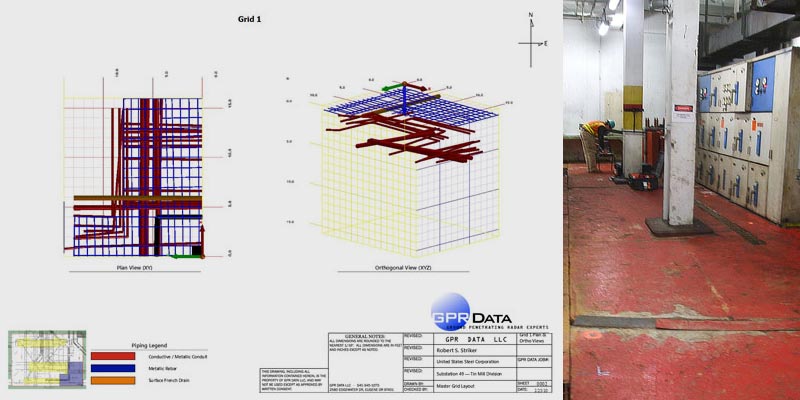

A sample of target analysis for one area of the floor follows, showing both a top-down plan view and an (X,Y,Z) orthoginal view of target depths.